Giles and Paula's Great Retirement Adventure

-

Long story short, Paula and I tried to pull the starboard rudder off the transom last Thursday. Rapid, unscheduled disassembly as American space PR people call it......

Damage to transom, rudder and rudder mount, and water coming into the engine room. Not in volume, but enough to be thankful for bilge pumps

Had her pulled out on Friday, first lift out of the day which I was very thankful for....

Today, Matt (a fishing mate) and I removed the rudder assembly to give the glass fibre guys access to the damage and the rudder assembly put in the car, so I can go from engineering firm to engineering firm trying to find someone who can unbend stainless steel, preferably in a hurry.

-

Double ouch.

-

Old school light engineering company 5 miles from here, has the rudder assembly and say that fixing the bracket is easy, a little unsure about the rudder stock itself. Will disassemble and let me know. I'm taking that as a moderate win.

Meeting glass fibre guy at the boat at noon to look at work required to transom. He does all the work for David and Alex Thomson and was recommended by them, so names dropped

I'm taking that as a win.

I'm taking that as a win.Feeling a lot more positive thatn I was at 07:00 this morning....

-

-

We need to cut a section out of the transom, the fibreglass layers have delaminated from the high density foam inboard and outboard (the hull construction from out to in is gelcoat/fibreglass/high density foam/fibreglass . Only a small area, but we need it cut out and rebuilt, otherwise the repair is structurally suspect. It's not an overly massive job, but does require time between process for stuff to cure etc. So we are looking at 2 weeks.........

I've heard from the machine shop, the bracket is an easy fix (just needs a shit ton of pressure and some straight edges), but the bend in the rudder stock (the bit that connects the rudder to the boat) is potentially problematical. They will try to straighten, but in the process may make it worse. So, I told them to go ahead, and if it is unsuccessful, we tum a new rudder stock and weld it to the rudder....

-

@Giles If everyone took care of their shit like you do, there would be much less of a need for newly built boats.

-

@Giles what is this knot called? I'd like to have a go at making some...

-

@Giles said in Giles and Paula's Great Retirement Adventure:

I have also made a few of these which are great:

I think Dita von Teese wears something similar.

-

Progress so far.

Mat and I took the rudder assembly off the transom on Sunday, leaving GRP and bolt damage. Oh and a big hole under the waterline (that is where the rudder arm comes through from the engine room and rotates the rudder)...

Was given some heat and 10 tonne pressure treatment yesterday, and is back waiting for the transom rebuild. Keen followers of this thread (all one of you) will remember that last time she was out of the water, I decided to polish the running gear and leave it bare. With her out of the water again, I have decided that I will polish the shafts and the props, and then coat with Lanolin, and prime and antifoul the P brackets, rudders and rudder housing. So I have started prepping the port rudder and housing for priming...

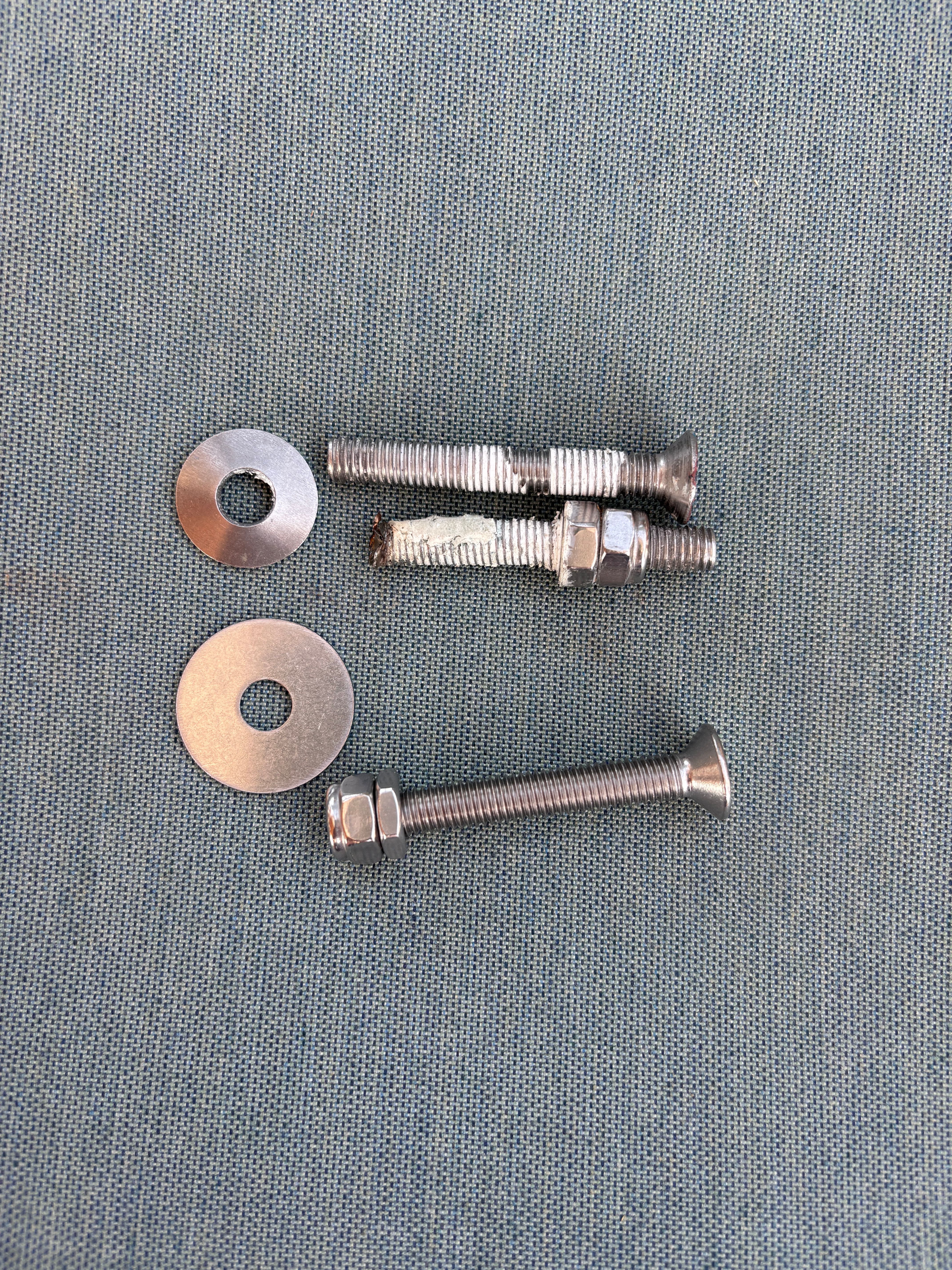

Started to buy the hardware required to reattach the rudder and housing. The original bolts are either bent and/or had to have the heads ground off to enable us to get the housing off. Top 2 are old, bottom one is new. I have also decided to increase the diameter of the penny washers...

Starboard prop and shaft before polishing...Carl, the GRP guy, suggested that I moved the shaft anodes back a foot or so, so that the forward section of the shaft gets more cathodic protection. Also, where I had originally placed them, would have caused turbulence near the props, making them less efficient.

Starboard, polished...

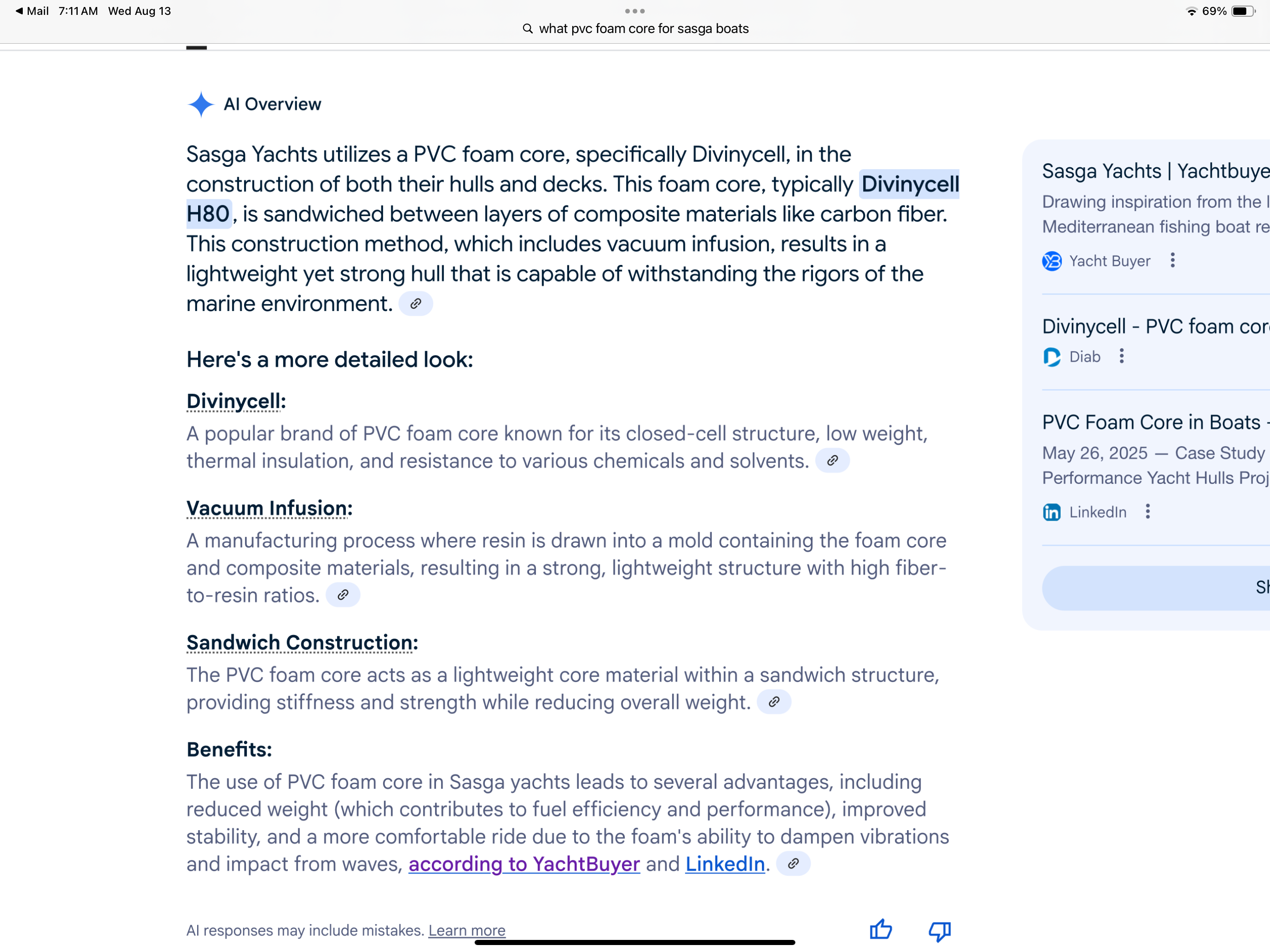

The Sasga factory is closed for annual summer break, so we can't ask them what type of high density foam they used, so we took a core sample and will try and determine what it is ourselves, you can clearly see the delamination too...

-

…and something else to check: https://www.compositesworld.com/news/mel-composites-infusion-strategy-enables-sasga-yachts-fiberglass-hull-designs

Edit: Specifically the naval architect Barracuda Yacht Design.

Might be able to reach them for specs on the transom repair. They should have details on materials used.